THERMOGRAPHIC TECHNOLOGY

Thermographic technology has many advantages for its use in diagnosis. In the field of refrigeration its precise measurement of temperatures can help to detect areas of wear and tear in a non-invasive way- alerting technicians of potential problems that would normally come up unexpectedly leading to down time and added expense.

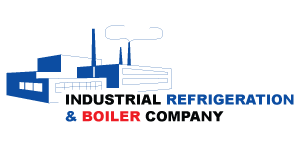

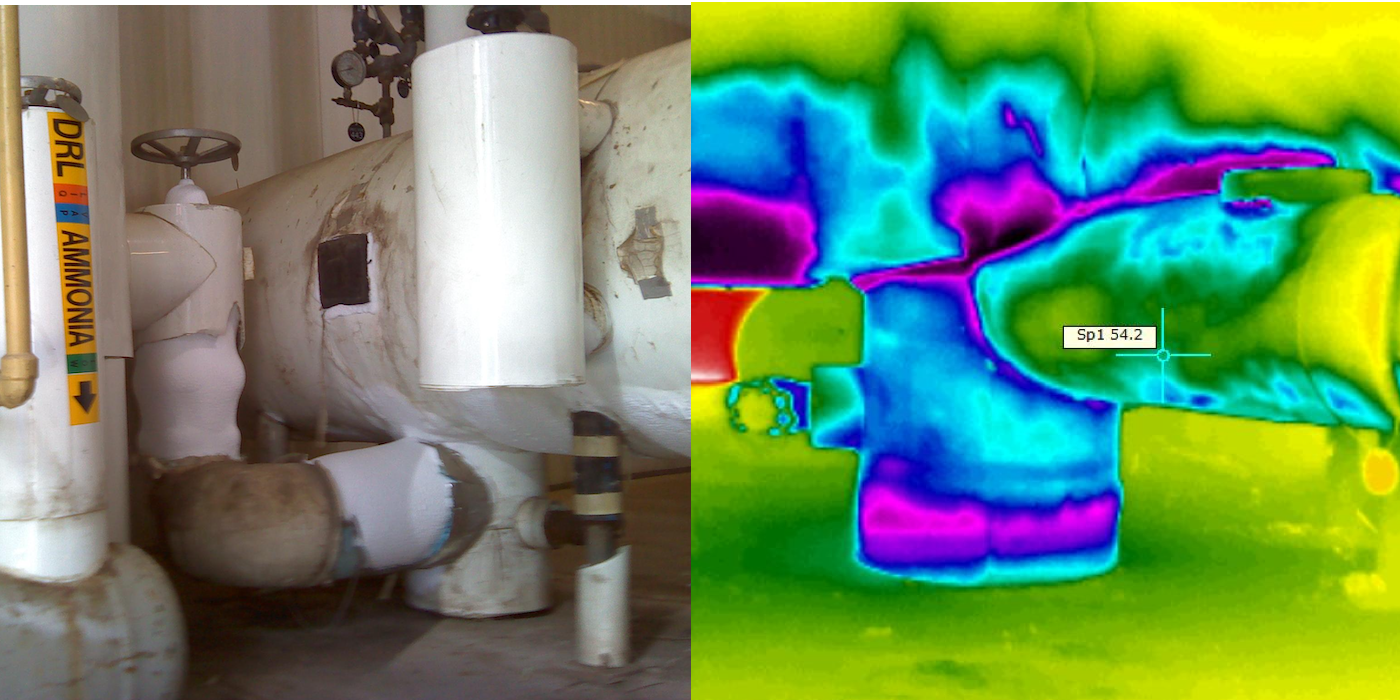

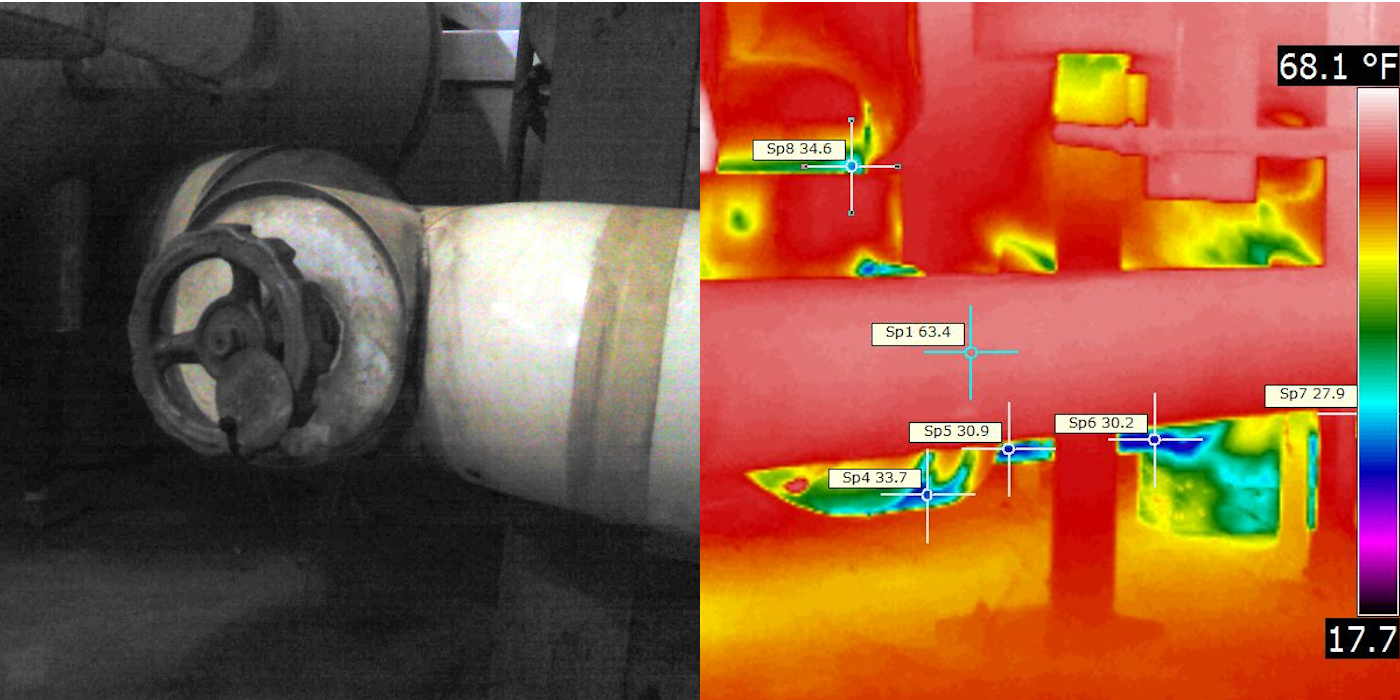

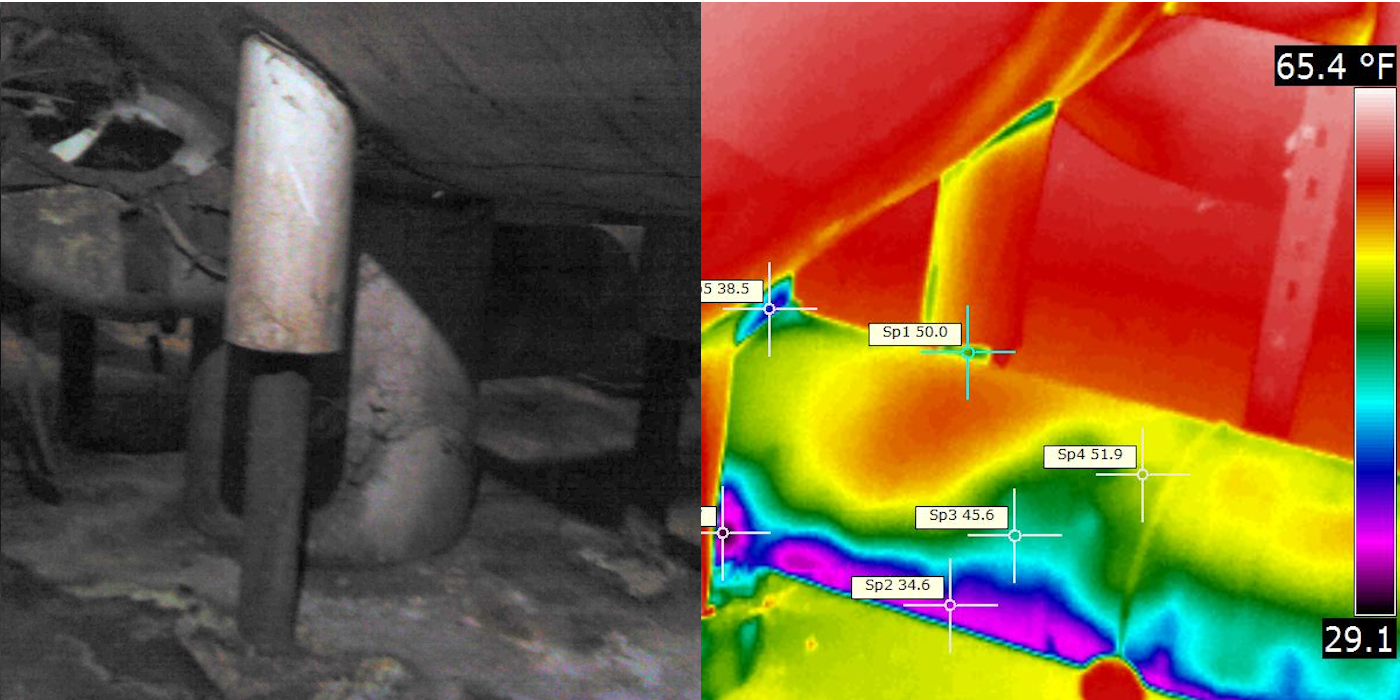

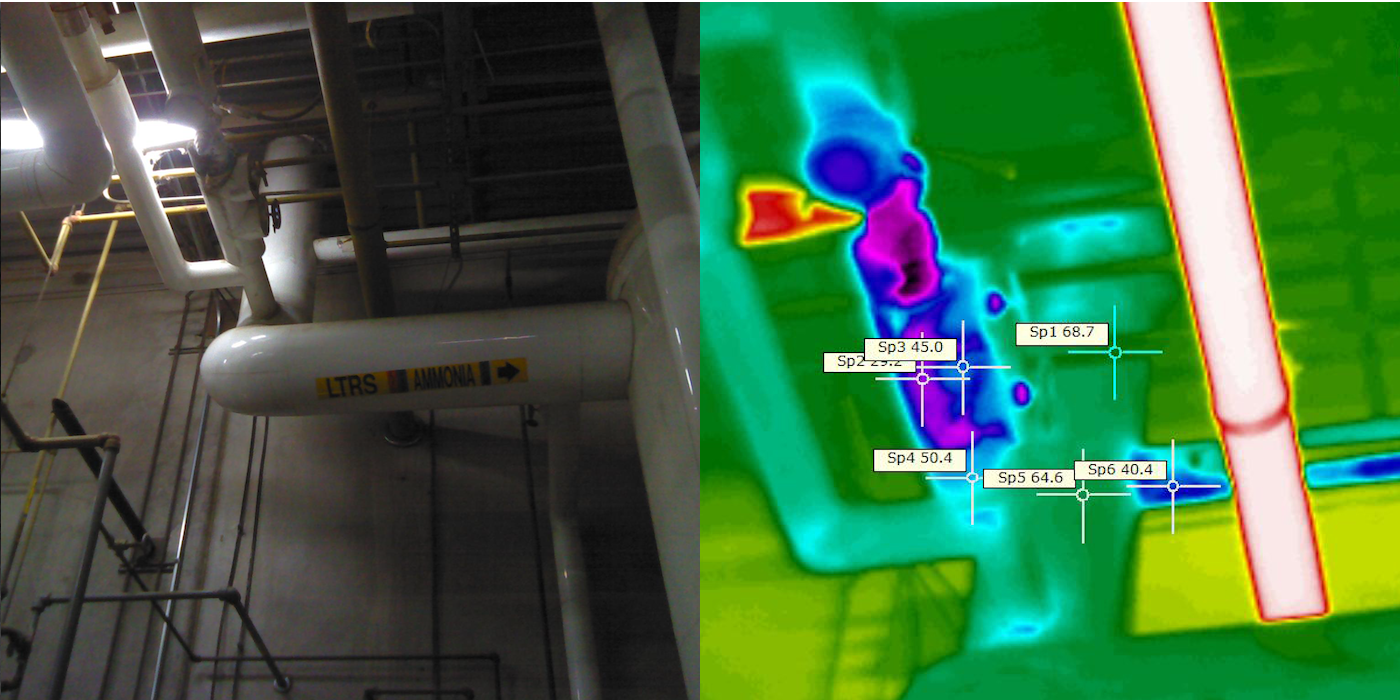

At Industrial our refrigeration specialists utilize thermography in order to pin point where moisture leaks are present in refrigeration system insulation systems. If moisture is present in the insulation system, the surrounding temperature differences can freeze-thaw system components and piping causing corrosion. This could result in piping and vessel failures causing leaks.

Our Fitness-For-Service Investigation Program will determine whether the vessel or piping is still viable for continued use, or whether replacement is needed. With the use of Thermographic Technology and Ultrasonic Testing which is used to measure the corrosion of material thickness, we are able to detect suspected areas of failed insulation and to further explore for possible Under Insulation Corrosion.

With the help of thermography camera we are even more efficient in our maintenance and service options – offering our customers the best possible service and maintenance program in the field.

Image Gallery